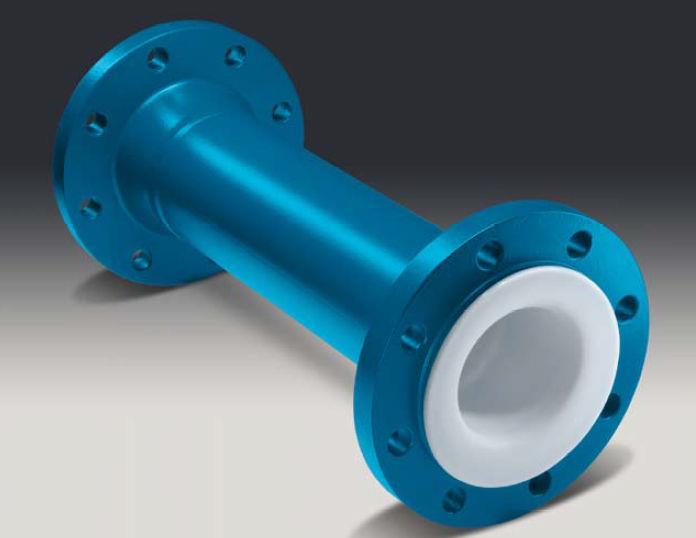

Steel lined ptfe equipment is usually made with discharge port, feed port, perspective mirror, etc., but how to successfully apply this kind of pipe port in the complex head intersecting line, of course, our answer is welding, then how to welding?How to control the temperature of ptfe welding?Below we tell one by one.

Steel lined ptfe equipment is usually made with discharge port, feed port, perspective mirror, etc., but how to successfully apply this kind of pipe port in the complex head intersecting line, of course, our answer is welding, then how to welding?How to control the temperature of ptfe welding?Below we tell one by one.

1, ptfe head pipe mouth production

PTFE pipe welding on sealing head to first of all, we should make PTFE sealing head nozzle, according to the size of the nozzle diameter steel head and according to certain proportion by using powder moulding process manufacturing nozzle, 8 hours of sintered under the 380 plus or minus 5 degrees Celsius, after the completion of the sintering good nozzle with lathe car to the right size, to the congratulations of PTFE tube at this moment you have finished.

2, ptfe head opening

Put the extracted head into the steel head, and use the principle of light transmission to accurately open the head, pay attention to the ptfe head must be consistent with the steel head, or the final equipment is prone to bulge, rupture and other potential hazards.

3, ptfe pipe mouth welding

By the first two steps, we can carry out PTFE welding. Here we know that there are two ways of welding (hot pressure welding and hot air welding). We will explain them one by one.

(1) hot pressure welding

Before hot pressure welding we should know the necessary theoretical knowledge, hot pressure welding is a kind of hot welding, provide sufficient heat and enough pressure.Here, we must ensure that the welding interface temperature must reach 673.15k and the pressure reaches 1-2mpa. Therefore, in order to ensure the welding, we need to make corresponding molds to ensure the successful completion of the thermal pressure welding.When all is done, the FEP film can be welded by pressurizing and heating the interface between the nozzle and the head.

(2) hot air welding

Similarly, ptfe hot air welding is a kind of hot welding, which is much simpler than hot pressure welding and does not require so many molds. After placing the pipe mouth, PFA welding rod and hot air welding gun higher than 713K are used to preheat PFA first and then place it on the welding seam for continuous welding.

Note: whether it’s hot pressure welding or hot air welding welding temperature will be higher than the melting point of ptfe, ptfe is possible under the temperature cracking, produces in the process of pyrolysis perfluorinated isobutylene and other poisonous gases, so the welding should be in a ventilation environment, when the condition does not allow such as the four fluorine lining tank welding in production must use the fan air supply air flow assurance and wearing a gas mask to ensure security at the same time.

Post time: Jun-24-2019