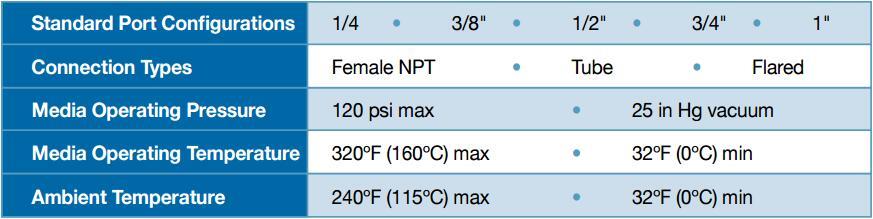

Polytetrafluoroethylene (PTFE), commonly known by its popular E.I. DuPont trade name polymer®, is also well suited to clean room and deionized water applications. The body, stem, ball and ports are constructed from PTFE.

Application

Tight-closing, PTFE-lined ball valve for process engineering and industrial applications, especially suitable for corrosive media.

Nominal size: DN 15 to DN 150Nominal pressure: PN 10Temperatures: −10 to 200 °C

Features:

PTFE construction for media wetted surfaces.Reliable low torque manual operation.Quarter Turn with Positive Stops.Design accommodates partial open position for metered flow.All models can be panel mounted.All models can be used in high ambient temperature environments.

Specification:

Principle of operation:

The process medium can flow through the Type PTFE Ball Valve in either direction. The ball with its cylindrical bore (ball channel) rotates around the center axis. The rotary angle of the ball determines the flow rate across the free area between the body and the ball channel. The ball shaft, which is guided to the valve outlet, can be optionally connected to a pneumatic actuator over an adapter or equipped with a manually operated lever. The ball is sealed in the PTFE lined body by means of exchangeable seat rings. The ball shaft is sealed with a maintenance-free, spring-loaded PTFE V-ring packing.

Post time: May-04-2019